Another method that solidworks uses is the bend deduction method.

Bend deduction sheet metal example.

Therefore the bend allowance added to the flange lengths is equal to the total flat.

Most sheet metal materials will conform to the calculations.

Bend allowance is a measure of how much extra material is required to accommodate a bend in sheet metal this is a function of the bend angle bend radius thickness of the material and a variable called the k factor bend allowances vary based on the angle of the bend the type and thickness of the material and the method used to create the.

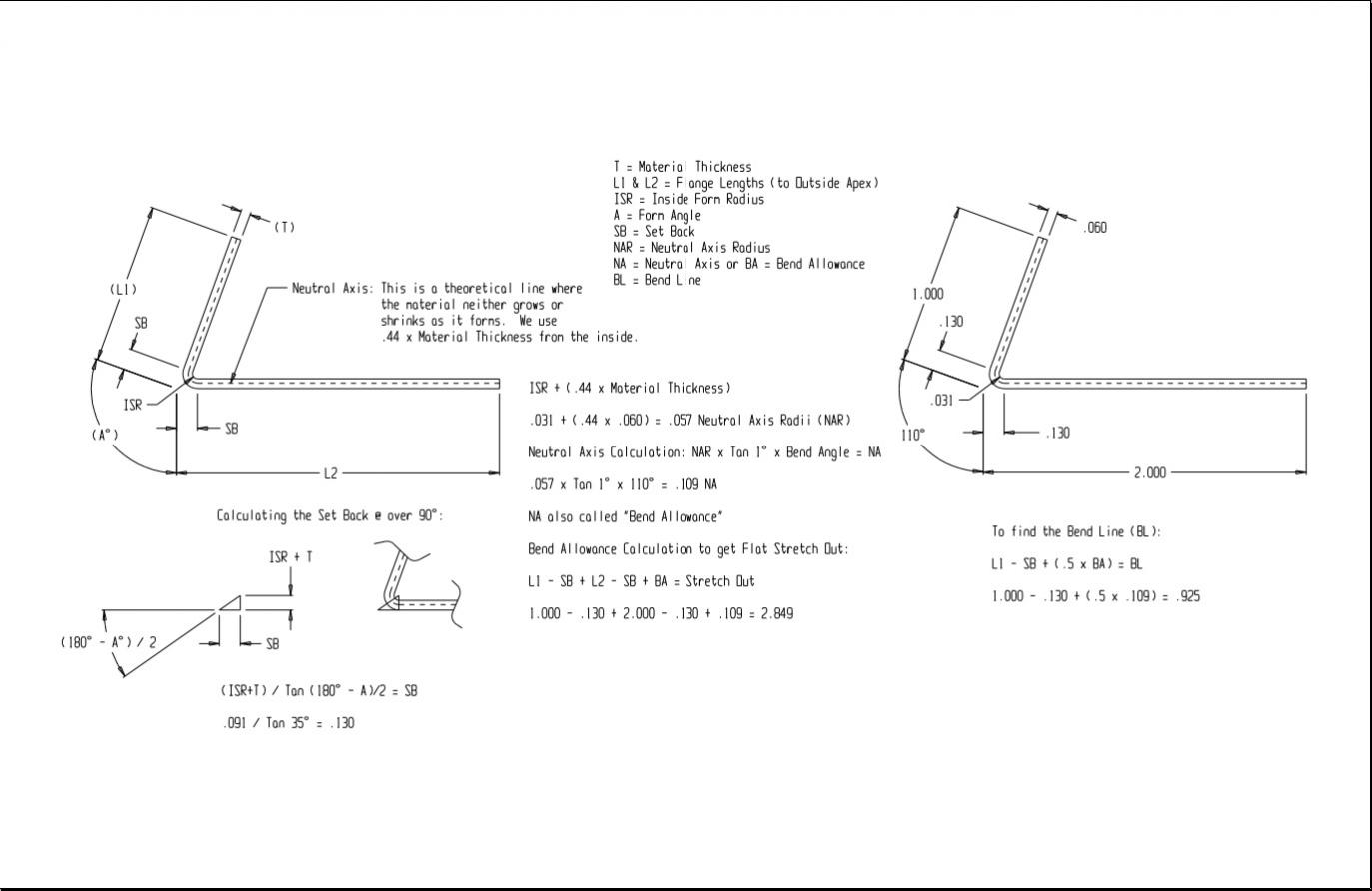

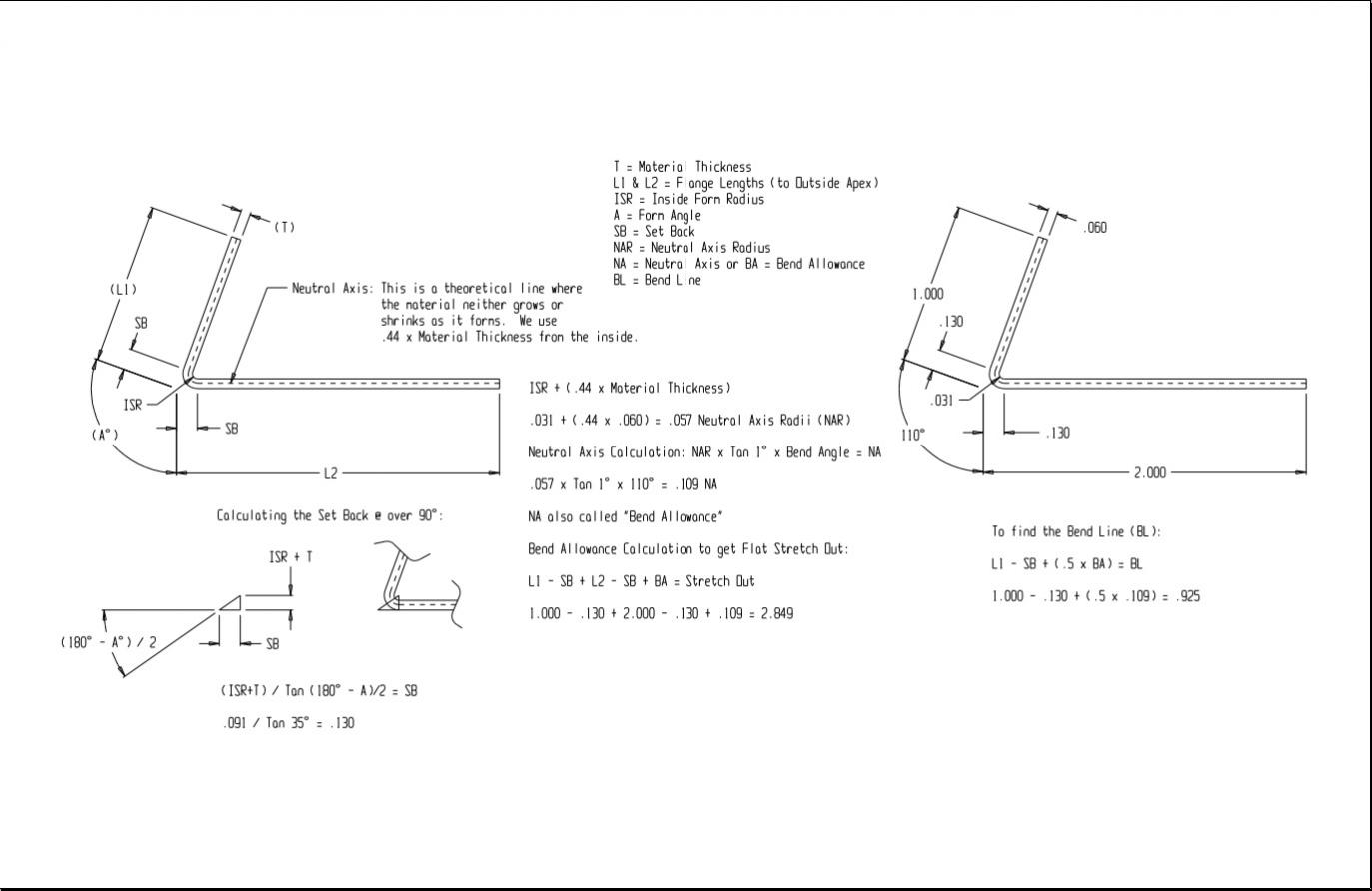

The bend allowance describes the length of the neutral axis between the bend lines or in other words the arc length of the bend.

Lf d1 d2 bd.

Understanding the bend allowance and consequently the bend deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated.

In order to develop the flat pattern we will subtract 293 from 5 to arrive at 4 707.

As with bend allowance bend deduction comes from the same sources tables and manual testing.

This is simulated on the part shown above by the section shown in red.

Should be subtracted from the flat pattern so the formed part arrives at the desired dimensions.

Bd bend deduction.

Sheet metal calculator bend allowance equations and calculator.

In order to develop the flat pattern we will subtract 293 from 5 to arrive at 4 707.

The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length.

The flatten length of the parts that are lf equals d1 plus d2 minus the bend deduction.

The force must exceed the material s yield strength to achieve a plastic deformation.

The bend deduction of means that the material is expected to stretch by that amount during the course of bending.

Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees.

The following illustration shows the equation calculation for determining the bend allowance when forming sheet metal.

This is done through the application of force on a workpiece.

When the bend deduction is calculated we find that it equals 293 in length.

Bending is one of the most common sheet metal fabrication operations.

In the example below the part has flange lengths of 2 and 3 with an inside radius of 250 at 90 will have a length of 5.

The formula is as follows.

When we calculate the bend deduction we find that it equals 293.

From there we can calculate the k factor and the bend deduction.

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

Childress last modified date.

This page also includes a link to a on line sheet metal bend allowance calculator.

When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched.

In our example below a part with flange lengths of 2 and 3 with an inside radius of 250 at 90 will have a total length of 5.