The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

Bend large sections of sheet metal.

Anchor bolts are used to hold the.

Material bend radii and minimum bend size charts please note.

Edge bending operations are commonly used in industrial sheet metal processing and involve bending a section of the metal that is small relative to the part.

These sections are located at the edges.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

Sheet metal isn t required to bend.

It can be cut into smaller pieces too.

As a result the wipe die also determines the bend s inner radius.

Self tapping screws are primarily used when fastening objects to.

The best saw for accurately cutting 3 inches off the length of a 2x8x18 inch piece of lumber is.

Edge bending is used to eliminate sharp edges to provide geometric surfaces for purposes such as joining to protect the part to increase.

Simple sheet metal bender using a hand roller clamps and plywood.

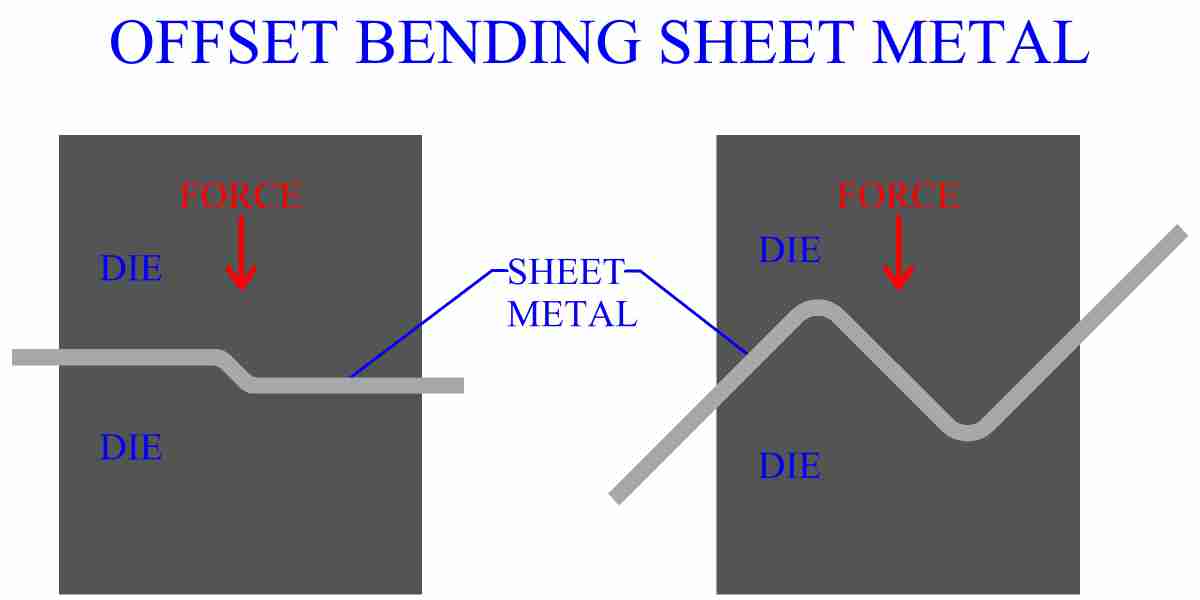

Wipe bending or edge bending is another way to bend sheet metal edges.

Bending sheet metal can be useful if it s used to build different shapes and different products.

These equipment considerations and processing tips can help make a big bending job easier to accomplish.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

Concrete blocks to the footing.

Which tool is used to bend large sections of sheet metals.

The slack between the wipe die and the punch plays an important role in getting a good result.

Monkeys spinning monkeys by kevin macleod.

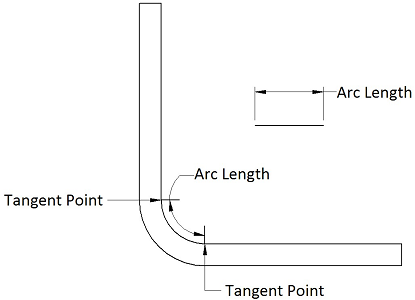

Step bending or bump bending is a method for forming a large bend radius in a sheet metal part without the need for special tooling by creating a series of highly open bends in close proximity.

Most frequently expensive sheet metal bending tools called brakes are used to bend sheet metal but you can also complete this task without one.

It is important to make sure that the sheet is properly pushed onto the wipe die.